G and M Code Programming Software Free Download Updated FREE

G and M Code Programming Software Free Download

What is CNC Programming?

CNC Programming (Calculator Numerical Control Programming) is the art of programming CNC machines to make parts. A CNC Program is a text file that contains g-code. If you're a professional who spends most of their time doing CNC Programming, your job title is probably CNC Developer.

What is G-Code?

Thou-Code is the language used to control CNC machines. It'south ane type of CNC programming that CNC programmers utilise, the other blazon existence CAM programming. CAM programs will generate m-code from a CAD drawing, but the end result is still g-code.

Your machine's CNC controller probably executes thousand-lawmaking, although at that place are other possibilities–Heidenhain, Mazak, Shopbot, and others have proprietary formats. Some machines with proprietary formats tin besides run g-code. Information technology is the Lingua Franca (working language) of CNC.

In order to make a part on a CNC car, you tell information technology how to brand the part using a K-Code Program.

What are the dissimilar methods of CNC Programming?

CNC Machines are programmed using ane of iii methods:

- CAM Software

- Conversational Programming

- G-Lawmaking Programming

Often, it's advantageous to use multiple methods together. For instance, yous might create an initial CNC program using CAM Software and then edit the g-lawmaking from the CAM Software using 1000-Code Programming to make the program manufacture a part faster.

Why should I acquire CNC Programming?

Every CNC machinist should know chiliad-lawmaking. If you're interested in CNC and machining, you should too.

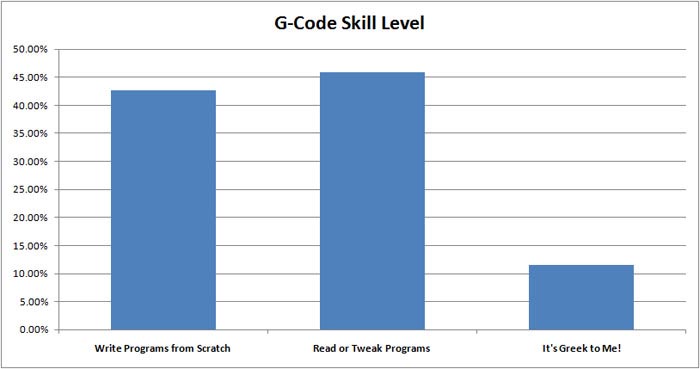

We recently did a survey to appraise the g-lawmaking skills of our readership. You lot should not be suprised to learn that many are quite proficient with Thou-Code:

Nosotros were impressed at how many readers can write g-code programs from scratch. In fact the overwhelming majority read, write, or tweak programs on a regular ground. If you lot're not yet able to do that, you need to learn if you want your skills to be on part with others.

CNC Programming can be a valuable skill to possess. Co-ordinate to Drinking glass Door, CNC Programmers receive an average salary of $54000/year. Compare that to CNC Auto Operators that get $42,000/year and CNC Machinist's who get $42,000/year.

Being a skilful CNC Programmer tin can boost your income pretty essentially based on those numbers.

Learning Conversational Programming is a offset. Picking up Conversational CNC along with some MDI piece of work will soon brand you as productive if not more productive than a manual machinist on a manual machine.

Getting skillful with CAM Software is even more important. You'll exist able to create parts that are just not possible to practice manually, or that would accept likewise long to exist worth doing.

But beingness a capable yard-code developer able to tackle macros and such is the final rung on the ladder. It may come up as a surprise to most CAM users, but at that place are many things a g-lawmaking programmer can do that simply aren't possible with CAM. In general, G-Lawmaking Programming is ideal for these kinds of tasks:

- Simple parts tin can be easier with grand-code than CAM. You want a rectangular cover plate with iv holes in it. If yous're proficient with g-code yous're washed earlier you can create a CAD model, run it through CAM, go the gcode onto the machine, and run it. With Conversational CNC, yous don't fifty-fifty have to be adept at g-code. For all those cases where you idea manual machining was faster, thousand-lawmaking or Conversational CNC will make the CNC automobile an fifty-fifty meliorate choice.

- Getting a Second Opinion on Your CAM Code. Even expensive CAM software tin can have bugs. Or, if they're not strictly speaking bugs in the CAM, they may be bug with the mail-processor. With but a little bit of knowledge most GCode and the aid of a GCode Simulator, you can get a second opinion on the CAM-generated GCode and set up minor errors before you take to discover them on the machine.

- Specialized or Downstream Tasks that Complement CAM. Equally great as they are, CAM programs don't do everything. There are many specialized tasks that are difficult or impossible to do with CAM. In add-on, there are downstream tasks–things that come upwards when the job is actually on the machine that weren't contemplated past the CAM or Post. Sometimes these tasks are relegated to GCode considering the CAM software won't do them. Sometimes information technology's because the CAM is aiming at a generalized common denominator and something special comes up on the Shop Floor–for example, a slightly different cutting tool has to exist used while we look for another shipment of the normal tools. A simple feeds and speeds alter in the gcode volition handle it far faster than re-running the CAM, assuming we're capable of making such simple changes.

For even more than details on those special tasks that complement CAM, cheque out 37 Things CAM Won't Do For You That G-Code Programming Can.

What's the Best Way to Learn M-Code?

The best way to acquire G-Code is slow and steady.

Find yourself a complete grade similar this one, start knocking out the lessons, work the exercises, and keep at information technology. Piece of work at your ain pace, and don't move on to the next lesson until you've worked the exercises and understand the material.

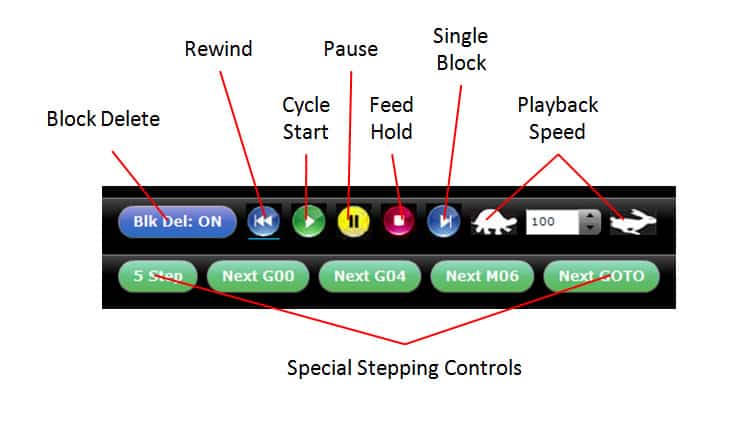

Working the exercises is a whole lot easier if yous've got some software to help y'all play with g-code. That's what our Thousand-Code Editor software is all about. Information technology simulates chiliad-lawmaking as well every bit decoding it for you. Yous tin can try out dissimilar m-codes and see visually what they practise. Experimenting is i of the best ways to get a proficient grasp of k-lawmaking. At the end of each department is a Quiz to examination your skills. Take the quiz and use the links on the questions to go back and review anything you missed so you'll be solid before continuing to the next department.

We encourage you to sign up for the gratis 30 day trial–that's plenty long enough to work through all the lessons free of charge. You lot'll find G-Wizard Editor not but makes it like shooting fish in a barrel to work with yard-lawmaking and try the exercises in the grade, but it has many features designed to make agreement the g-lawmaking easier. For example, it offers "Hints", where information technology takes each line of thousand-lawmaking and explains in plain English what that lawmaking does. In that location's nothing else like it available anywhere. For more information,visit the GW Editor Home folio. Or, go head and sign upwards now for the free xxx days:

In that location Are Many Dialects of G-Code

Some wag once joked that the great thing about standards is there are so many to choose from.

At that place are many G-Code standards and dialect. While much of information technology remains the aforementioned from controller to controller (setting bated alternatives to M-Code from things like Mazatrol, Heidenhain's Conversational CNC language, and others), there are of import details and defaults you lot need to be aware of to empathise the particular dialect of thousand-code your controller needs to be happy.

In terms of sheer numbers of users, the Fanuc dialects of One thousand-Code are probably the most common amid professionals and Mach3 amid hobbyists. This is not to say they are better than other Thousand-Code dialects, just that they are more common and then if you lot're going to talk to other machinists or motility around from task to chore and car to auto, it may be helpful if y'all're familiar with those dialects and how they differ if your car doesn't employ one of these two controllers.

For more details on the relative popularity of different dialects, check out our CNC Controller Survey.

Grand-Code has an extremely long history. The first attempts at standardizing it came out of the Electronics Manufacture Association's RS-274 standard which has evolved to NIST'southward RS-274NGC standard. The original EIA standards work was begun in the 1960's simply the commencement standard wasn't released until 1980. Even though at that place are now standards (ISO has i too that is almost the same every bit RS-274), information technology isn't articulate how many controllers out there are purely standards based. Indeed, many controls will claim to exist some standard or other, but when you look closely at the details they're pretty non-standard.

How Are the Dialects Different?

G-Code dialects differ in a variety of ways. Virtually manufacturers accept added their ain lilliputian bells and whistles to make their dialect better for competitive and marketing reasons. For example, Haas has a series of special g-codes for pocket milling, too every bit some special parameters and capabilities on some standard G-Codes. It pays to sympathize the special capabilities of your machine because they were probably put there to salve fourth dimension based on feedback the manufacturer got from its customers.

In general, we see the following categories of differences between G-Code dialects:

– Which Chiliad-Codes are Supported. Not all controllers support all 1000-Codes. For example, many early on lathe controls practise non support the G71 and like roughing cycles.

– G-Code mappings. Sometimes the same function volition be supported past different yard-code numbers on different controls.

– Parameters and Macro Programming. Parametric programming with macros is something that emerged after the basic standards were in place. Fanuc Macro B is probably the virtually common standard for it. Many controls are very limited in their capabilities effectually Macro Programming and there are a lot of detail differences around exactly how Macros work.

– Parameters. Many One thousand-Codes need boosted information to exercise their chore, so they apply other words (messages) to collect that information. Exactly which words collect which information can vary from ane command to the next.

– Formatting. Some controls allow G0 or G00. Some insist on G00. Some allow numbers with no decimal, others insist on a decimal or even a trailing naught. "ane", "1.", and "i.0" are all variations that may be accepted, rejected, or required when specifying the number 1.

We'll talk more shortly most what all of this means, but for now, exist aware that these differences be. For simple programs and MDI use, obviously a lot of this won't affair. Merely, for writing circuitous hand-written G-Code or trying to understand why the 1000-Code your CAM program emits isn't quite right, yous'll need to be aware of the dialect issues.

Very Of import:

For purposes of this tutorial, unless nosotros specifically say something different, we're going to assume you're running a Fanuc controller. If you follow along with our exercises with G-Wizard Editor, you should run a Car Profile for the Fanuc Controller, preferably by downloading our canned contour. When you go to plan for your machine, you'll need a profile properly gear up for your auto!

How do the Dialects touch on CNC Programming?

Plainly you need to be enlightened of what dialect you need to target for a CNC Program to run on your CNC Machine, but how do these dialects touch on CNC Programming?

CAM Software uses what's called a Post Processor to deal with g-code dialects. The role of the postal service processor is to translate an idealized language that's usually internal to the CAM Software into a specific g-code dialect.

To learn more than about Post Processors, check out our article on them.

Exercises

1. Look up what thousand-code dialect your CNC machines use. Are they Fanuc? Mach3? LinuxCNC? Or something else? Does the manufacturer claim compatibility with a standard?

If you're a transmission machinist, retrieve of a CNC Car equally being just like a manual automobile that has ability feeds and DRO'southward (Digital Readouts) on every automobile axis. There'due south more to it than that, but if you lot call back of the machine that way, you become an idea of what you can arrive do very quickly in one case yous learn how. And, in that location isn't really that much to larn either.

CNC Coordinate Organisation for G-Code and Machines

The very first thing to sympathize is the CNC Coordinate System.

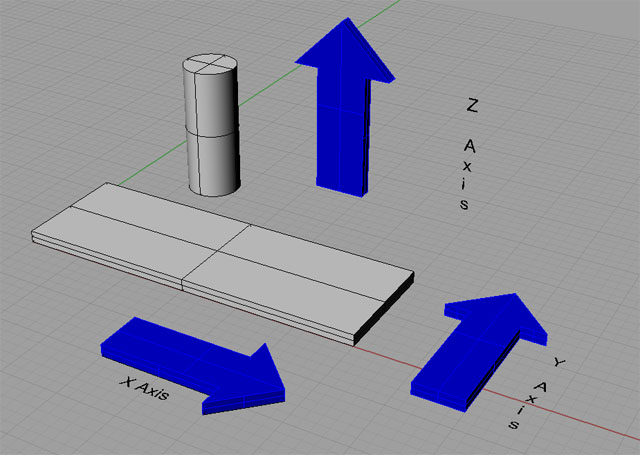

Each automobile has its own specific axis orientation, and you'll need to be familiar with how your car's axes are oriented. Hither are some common types:

Factory Axes for a Typical Vertical Machining Center. Note: arrows prove tabular array motion in positive g-code direction. Handedness is spindle motion and reversed!

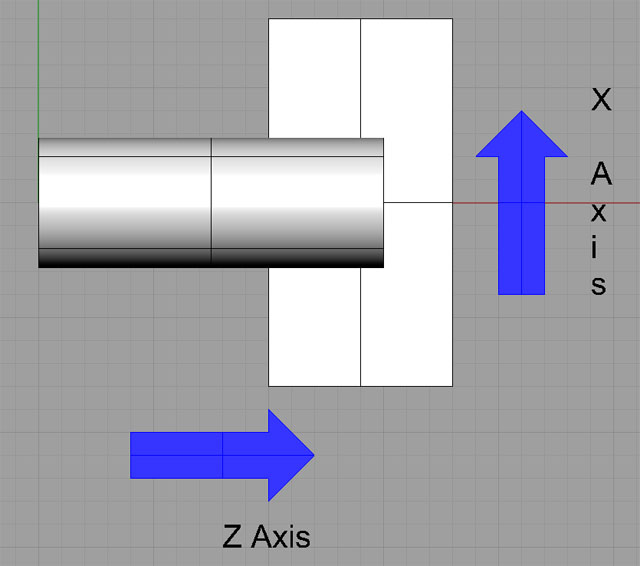

Lathe Axes for a Typical 2-Axis Lathe…

The cylinders in each cartoon represent the spindle of the automobile. Be sure to have a look at exactly how the axes are laid out on your machine. For example, horizontal mills are turned around considerably from the cartoon I've shown. Lathes can become a lot more complicated than the simple ii-axis version I've shown.

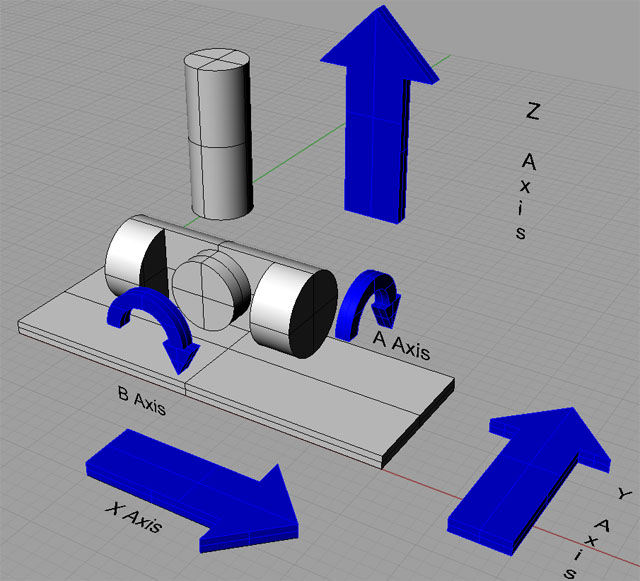

4-Centrality, 5-Axis, and More

Much more complex configurations are possible when y'all accept more axes. For example, here is a 5-axis setup:

5-Axis Mill With Trunion Table…

Note that we take added tworotational axes to the bones manufactory diagram to provide an A-Axis and a B-Axis. In general, A, B, and C are rotational axes that rotate around axes formed by the X, Y, and Z respectively.

Expressing Coordinates in K-Lawmaking

At present that we know what the coordinate systems are, how exercise we limited coordinates in G-Code?

It's pretty simple: just take the axis letter and add the value. Spaces between the letter of the alphabet and its value are optional.

For example, a position that is 1 inch from 0 along X, 2 inches along Y, and 3 inches along Z is written as:

X1Y2Z3

You get used to reading them all run together like that quickly, but y'all tin can format them with spaces to make them more readable:

X1 Y2 Z3

or

X one Y 2 Z 3

Again, you lot become used to keeping the letters with the numbers, and so I wouldn't add more spaces than simply betwixt the axes:

X1 Y2 Z3

That's really the easiest to read once you become used to it.

What Nearly Units?

The instance I just gave used inches, but in authenticity the controller can be set to use either metric or Imperial. It'southward up to you lot to know which default the system comes up in and to change the units equally needed. Try not to modify units in the center of a plan, practice then at the very starting time and and so stay with the aforementioned units. It's too confusing otherwise. The G-Codes to alter units just affect how the machine interprets the numbers. They don't alter your program. We'll talk more about changing units in a futurity article, simply for now, just exist aware.

For rotational axes (which you'll just be using on a 4 or 5 axis automobile), we don't employ dimensions for the units, nosotros employ angles, typically in degrees. Rotating the fourth centrality to the 90 degree position might be done as A90, for case.

Incremental Versus Absolute Coordinates

Sometimes, it is very convenient to refer toIncremental orRelative instead ofAbsolute coordinates. Let's assume the tool tip on my manufacturing plant is at X0 Y0 Z0 and I want to movement it to X1 Y2 Z3 (I dropped the commas, which are non used in G-Code, considering I'm just trying to get you used to the switch from how you learned coordinates in schoolhouse, e.g. (0, 0, 0), to how information technology'due south done in One thousand-Code X0 Y0 Z0). I can make the move accented or incremental and it doesn't matter. "X1 Y2 Z3" does the fox since in either case we started from X0 Y0 Z0.

But, suppose your cutter is positioned at some point and you need to cut a one″ square with the corner aligned to that betoken. Perhaps you've used your edgefinder to locate the cutter precisely on some feature of the part. This is easily done with relative moves:

X1

Y1

X-one

Y-i

In essence, motility ane″ right, 1″ upward in Y, one″ left, and and so 1″ downwardly in Y. Now we have a i″ square whose lower left corner is the initial point.

In that location are lots of cases where relative moves are handy so the ability to switch dorsum and along comes upwards a lot. We'll show y'all how to make that switch when nosotros talk about how to move with G-Code, but for now, simply be enlightened that there are both Incremental and Absolute Coordinates.

Sometimes, we refer to relative coordinates with special axis letters. For example, IJK may be relative XYZ when defining arc centers. On some controllers, UVW may be used alongside XYZ to refer to relative coordinates without needing to change back and along between relative and absolute modes. In other words, XYZ is used always equally absolute and UVW is always relative.

For at present, information technology is plenty to be aware that incremental coordinates exist. A little later, we have an entire chapter but on the bailiwick of incremental versus absolute coordinates.

Offsets

The final Coordinate Organization concept I desire to cover is that of Offsets. Offsets are some other fancy way to think most relative motions. Let'due south suppose you lot want to motorcar 2 identical parts. Each is held in a vise on your table at the same fourth dimension. How do you make one program that can do both parts without having to alter the program for the position of each part?

The reply is that we use a Piece of work Offset. More than detail on those later, merely for now, imagine that Work Offsets let usa position the X0 Y0 Z0 origin in more than i place. We can put one on the showtime vise and another on the second vise. At present just by changing the work kickoff the same program can piece of work to make the part on either vise.

There are lots of different kinds of offsets in CNC, and the skilled CNC operator/machinist finds that offsets are an extremely handy way to nudge the behavior of a G-Lawmaking Program without having to change that program. Most CNC controllers have an offsets screen where you do that. I mention this because any fourth dimension you get a chance to acquire about offsets, accept the fourth dimension to do and then. They're digital power tools for the CNC machinist and are very handy. Nosotros'll cover them in greater detail later on.

Planes

Information technology's convenient to refer to planes for various purposes. A plane is a flat 2 dimensional space defined past ii axes. For example, the default plane on most mills is XY. If y'all draw an arc without specifying a change in the aeroplane, it will be drawn on the XY plane. There is a plane for each combination of the linear axes XYZ:

- XY

- YZ

- XZ

The G17, G18, and G19 Chiliad-Codes select which airplane is active. More on G17-G19 when we talk more than almost arcs.

Conclusion

You lot've now got the nuts:

– You know how to visualize the coordinate systems relative to your motorcar using the left handed rule.

– You know how to express coordinates in Chiliad-Code.

– You know what units are used to measure the coordiantes.

– Y'all know there is the possibility of both relative and absolute coordinates.

– You lot know that offsets let yous shift the coordinate system around for various handy purposes.

– You know about planes.

Nosotros'll shortly introduce the notion of MDI, which is a unproblematic mode to apply K-Code as though you are yet a transmission machinist. It's a proficient introduction to the basics of moving your CNC'due south axes. Just offset, nosotros need to get you ready on G-Wizard Editor so you'll have a CNC Simulator to apply for practice during these tutorial lessons.

Hey i more thing, only in case you lot were wondering. About CNC grand-lawmaking dialects also have Polar Coordinates. information technology's a more advanced topic that we'll get to later.

Exercises

1. Leave the transmission for your machine and find the diagram that shows how its coordinate organisation works. Brand sure to leave the manual handy, whether information technology is paper or online. We'll refer back to it a number of times as nosotros get through the various exercises.

2. Bring up G-Wizard Grand-Code Editor. By default, y'all're in Manufacturing plant Mode. There are views for Perspective, Acme, Front, and Right. Download the sample engraving file from our download page. You want the file chosen HomeSwitchRearPanelEngrave. Start up GWE and do a File Open up to load the downloaded file. Have a expect at information technology in each view.

– Top is a view from the XY aeroplane

– Front is a view from the XZ plane

– Right is a view from the YZ airplane

In that location are basically 4 kinds of CNC Programming Software that will assist you lot produce good g-lawmaking for your CNC machine:

- CAM Software

- Chiliad-Code Editors

- G-Lawmaking Simulators

- Conversational Programming Software

Permit's go over each to come across how it can help you be more productive every bit a CNC Programmer. BTW, there are a ton of other kinds of CNC Software besides packages aimed directly at CNC Programming. For a good overview, see our article, "Complete Guide to CNC Software:

21 Kinds of Digital Tooling for CNC".

CAM Software

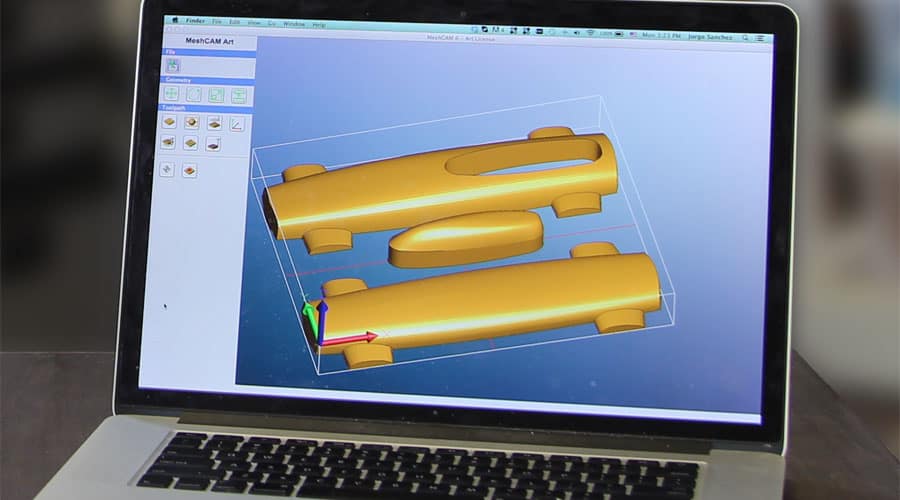

MeshCAM: The world's easiest CAM software…

We talked a fleck about CAM Software already. It's used to convert CAD drawings (or 3D Models from CAD) into g-code. 3D Printers apply software chosen "Slicers" that does the same job.

Since this Guide is largely about programming in chiliad-code, nosotros won't spend a lot of time talking about CAM. Simply, if you want a quick run through of the basics, endeavor our article, "Secrets of CAM for Beginners." It's got a lot of cracking info and even walks you through making the same part using two different CAM packages.

G-Lawmaking Editors

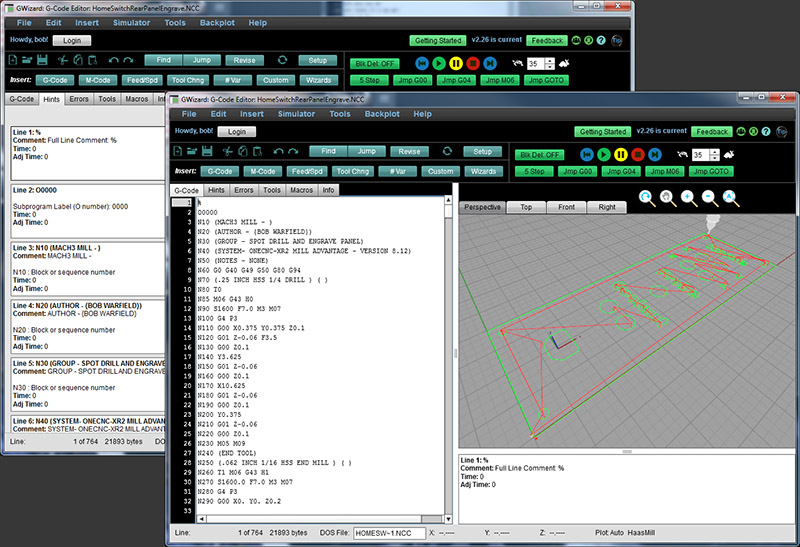

The virtually bones tool for cnc grand-code programming is but called a "G-Code Editor". Our very own G-Wizard Editor is once such program.

Why non simply apply a text editor for cnc programming? After all, 1000-lawmaking is just text.

You could employ a Notepad or some similar text editor. Many CNC'ers do. Merely they're missing out on the significant productivity gains a good G-Lawmaking Editor tin provide, such as:

- Text Editing Features: These features make up one's mind how easy information technology is to edit the text of your programme. The of import thing is that these features know one thousand-code syntax, and are not just the standard features any text editor has.

- Informational and Ability Editing Features: These features give you extra ability in agreement your program, or in creating it quickly.

- Program Revision Features: The features help you to brand mass revisions to your programme, for example, to renumber the program lines.

- G-Code Simulator and Backplotter Features: These features allow you to watch the yard-code programme execute in simulation.

- Error Checking Features: If your goal is to brand certain the gcode is prepare to run when information technology hits the CNC machine, y'all desire to have comprehensive error checking right in your Editor/Simulator.

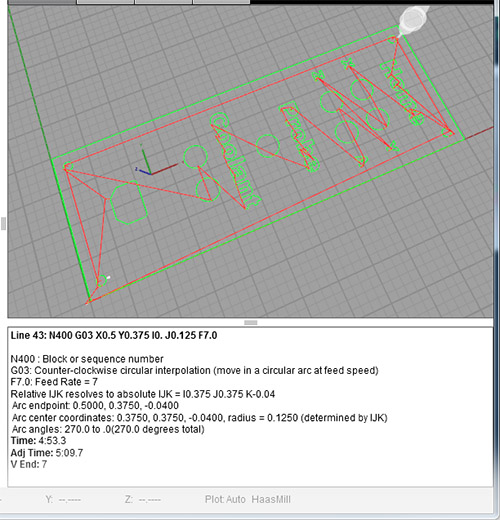

Advisory Features: G-Code Hints

1 of the best things about our Grand-Wizard Editor is it gives yous hints in patently English that tell you what each line of g-lawmaking does. The hint appears right beneath the backplot:

In improver to the hint that G03 is a counter-clockwise arc, look at all the additional information that'due south given:

- Arc endpoints

- Arc centre coordinates

- Arc angle

None of that is obvious only looking at the g-code plan, especially in a text editor.

Special Ability Editing Features

As you learn more than nearly g-code'due south construction, you'll come to appreciate the ability editing features a adept m-code editor can provide. For example, lines of g-code are frequently numbered. What a pain it is to renumber by hand, but the g-lawmaking editor tin do that for you automatically.

There's a lot more a good g-code editor tin can practice. Dig more than deeply into them with our article on CNC Grand-Code Editors.

Thousand-Code Simulators, Debuggers, Backplotters, and Viewers

G-Wizard Editor'due south Macro Debugger command panel…

While most Yard-Code Editors include a built-in Simulator, they're not all of equal power. In addition, you can buy Simulators that don't include an Editor. I'thou not dominion sure what the value of that might be, but they're out there.

Simulators may too be called Debuggers, Backplotters or Viewers. Their role is the same. They simulate the execution of your g-code in the g-code dialect y'all've selected. You can run into the graphical backplot of the toolpath in the G-Wizard Editor screen shot above.

You tin tell at a glance from a backplot exactly what moves the tool will make when the program is run. A very high quality simulator (similar the one in our K-Wizard Editor), has a more than capabilities than simply a backplot:

- Your CNC Machine has what are called alarms. Certain things volition trigger an alarm even though the backplot looks fine. A practiced simulator has alarms too so yous can check your plan and set all the alarms before they prove up on the auto.

- Macro Debugger. This is the power to test and thoroughly understand g-code macros. Macros are the ultimate in CNC Programming power and flexibility, but they tin be quite complex to create, understand, and debug. Hence a Macro Debugger is a valuable banana when dealing with them.

- A Post Processor, just like your CAM Software uses. Well-nigh simulators don't have a post. They brand a lot of assumptions, which means they tin't accurately identify problems relating to grand-code dialect. You want a simulator that has a post.

G-Wizard Editor has all 3 capabilities and more than.

Doesn't my CAM Software already take a Backplot / Simulator for this purpose?

This is one more than thing to look out for, because the qualified answer is, "Maybe." The issue is how the CAM program's simulation is generated. If your CAM programme includes a true CNC g-code simulator, and so yes, information technology does accept a simulated backplot and by all means use information technology.

The thing is, near CAM programs don't. They just plot the same geometry information that was used to create the g-code output by the postprocessor. This allows for subtle bugs to pitter-patter in that are not detectable in the CAM backplot.

Considering of that, a lot of experienced machinists insist on a split simulated backplot as a sanity bank check for their grand-code before they'll run it. It doesn't cost very much or take very long to take this peace of heed, so it's something you should consider.

For a actually deep dive on CNC Simulators, check out our article.

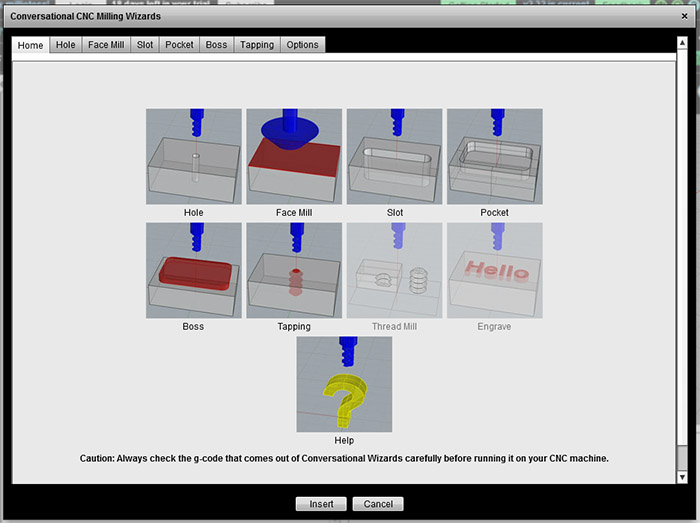

Conversational Programming Software

Forget CAD and CAM. What if you just want to make a simple rectangular bracket with four holes? What if you lot need to turn a little spacer on your lathe? Practice you actually need the full power and complication of those things to go those uncomplicated jobs washed?

No, of class non. But, if you don't have Conversational Programming, y'all may detect yourself either dealing with CADCAM anyhow, or slinking back to the erstwhile manual machines in the dorsum of the shop to get those simple jobs done.

Conversational Programming is built right in to G-Wizard Editor…

With Conversational CNC, you pick a generic performance, such as making a hole, and you're presented with a unproblematic make full-in-the-blank Wizard. Reply a few questions, push button a button, and yous get chiliad-code to do the job.

Conversational Programming can be its ain software (it's built right into our G-Sorcerer Editor, meet how here) or it tin be built into your motorcar's controller. Either way, it's very handy for simple jobs.

To learn more about Conversational Programming, check out our in-depth commodity.

Which one is right for yous?

It'southward a play tricks question. By now I hope you can run across how you'd benefit from having all of these tools bachelor. They volition all relieve you time. Even if you don't programme to do any hand editing of m-code, having a Yard-Code Editor/Simulator will assist you brand sure the CAM code is prepare to run on your machine. It simply takes a few seconds to bank check the code when information technology comes out of CAM, and it can surely salve you lot some fourth dimension.

With the right software, you lot don't need too many packages though. Add G-Wizard Editor to your CADCAM software and information technology comes with the Editor, Simulator/Debugger, and Conversational Programming. Why be without it?

You've learned a lot. If you followed through with the last v chapters and spent a little fourth dimension drilling down into our grand-code cheat sail, yous're ready to tackle some simple programs. There'due south just ane more thing you need to consider, and that'south the machine setup work that goes hand-in-paw with any CNC program.

Permit'southward Get-go With Function Zero (besides known every bit Plan Zero)

We've already discussed CNC Coordinate Systems in a previous affiliate, and so allow's talk almost how to gear up a machine coordinate system so information technology matches up to the function you desire to make.

Allow's suppose you just got done cartoon upwards a office in your CAD software, and you're about fix to generate some k-code for it. One of the central things to empathize is where Part Nix is going to be. Your CAD plan has some sort of coordinate system, and your part is positioned in the drawing relative to that coordinate arrangement. If you've never done any CNC work before, you lot may not have paid much attention to that positioning. Perhaps you stuck the part well away from the 0, 0, 0 origin in the CAD program then it would exist easier to see without the centrality lines being too close.

Yous might want to reconsider that idea, at least until you lot go very comfy with all the unlike coordinate systems that you'll be using for CNC. Instead, what you lot desire to do is put your "Part Zero" (for at present, the CAD System's origin or 0, 0, 0) some identify that makes sense when you become set to machine the material. When your k-code plan refers to X0 Y0 Z0, that's your Office Zilch. Later on we can become all fancy with Work Offsets and other means of transforming the coordinates, merely when you commencement starting time the car, think of X0 Y0 Z0 as Part Nada.

There are a lot of unlike theories on where to put Part Zero, and it matters for how easy and natural your CNC piece of work will be.

When milling, a lot of emphasis is on the Z axis. When Z = 0, where should that be in relation to the office?

1 theory has Z = 0 being the top of the workpiecebefore machining. This facilitates knowing when your cutter is cutting workpiece and when it is cutting air. Of form as you start making chips, you're also making air downward below Z = 0, but it is still a comfort to know where that original boundary started.

Another theory prefers that Z = 0 be some feature that doesn't motion and will not exist milled abroad. For example, it might exist the acme of a vise jaw. This is handy should y'all need to remove your part for some reason. You won't accept to re-reference the machine to a new Z0. It is also handy if you lot're machining workpieces with slightly differing dimensions. For example, fifty-fifty if yous're making identical parts, you may be starting with rough sawn material. The exact coordinates of the top of such material will vary from workpiece to workpiece considering sawing is non a precision functioning.

Cookbook Recipe: I like to use a Function Zilch that corresponds to the fixed jaw of my vise when I will use a vise for machining. Once y'all get used to making your CAD drawings with that in mind, information technology means you can walk up to the machine, stick a piece of material in the vise, load a k-code program designed with that notion of Office Nix, and immediately begin machining after just homing the machine. Since the vise generally stays put on the machine, there are no touch offs required, which is a nice productivity booster. If I practice demand to motility the vise or change jaws, no worries, I can just rezero on that location again.

Any yous decide to use for your Office Zero, you lot demand to be enlightened of information technology, and it is worth thinking virtually how to choose a Function Null that might save you a little time or make things easier to empathize.

What's the difference between machine zero, work zero, part zero?

Auto Zero is the origin of the coordinate organisation that corresponds to the machines centrality travels. Work Zip and Part Zero are the same thing, and they are the origin of the Work Coordinate System. Put some other way, Work Zero/Function Zero constitute a WCS past defining its origin. Your CAM plan will accept a fashion of specifying the WCS or Part Zero. When you lot setup the job, you will use edge finders or other sensors to tell the machine exactly where Part Zero is.

When you start upwards the motorcar, it doesn't necessarily know anything well-nigh your preferred coordinate system. What it does know is something called "Machine Coordinates". This is a fixed coordinate organisation that is baked into the auto. When you "Abode" the machine, or "Reference the Axes", you are causing it to utilize its Home Switches to accurately locate itself relative to car coordinates. If your auto doesn't automatically home when you showtime it up, information technology'due south a good thought to get used to the idea of homing it before you practise much else. If you crash or emergency stop, information technology tin can also be a adept idea to dwelling the machine so it tin can pick up its lost position.

"Work Coordinates" are the coordinates you want to think about. In other words, Work Coordinates are the ones where the motorcar is at Part Nada when its display shows X0 Y0 Z0. For that reason, Part Zilch may also be called Work Zero. You lot tin can establish Work Coordinates in a diverseness of means. By "institute", I mean you tin can tell the machine how to equate Piece of work Coordinates to Machine Coordinates.

A Work Coordinate system is something your auto will remember from ane invokation to the next, though y'all probably shouldn't count on that unless you know for sure you can. Since I utilise the system of Part Zero matching a point on my vise jaws, I can commencement the auto and Domicile it and I know the Piece of work Coordinates are what I expect. Y'all also take the ability to establish multiple Work Coordinate systems, which is convenient for a lot of reasons. Nosotros'll talk more about using multiple Work Coordinate systems in a later article. For now, permit's just focus on i.

Establishing a Piece of work Coordinate Organisation via "Touch Offs" or "Zeroing"

Permit's talk about establishing a Work Coordinate system via Touch Offs. We'll use my vise jaw organisation, only to make the discussion concrete, just the principle works for any work coordinate system.

Simply put, a "Touch Off" is where you lot use the cutter to locate the Piece of work Zero. We practise it one centrality at a time, so permit'due south start with the "Z" centrality. There are lots of ways to do Touch Offs. Each has varying accurateness and requires you lot to work on your technique a bit. The Old School method uses paper–cigarette rolling papers were very thin and commonly available. Use a lilliputian dab of oil to agree the paper in place and slowly jog the spinning cutter until it moves the paper. Stop. The cutter is now located at the Zip, with the exception of the thickness of the paper. Some trial cutting and a micrometer will establish what that is. Be certain to utilize the same kind of newspaper each time so the thickness is repeatable.

A more modern and accurate method would involve the utilize of a cuff block. Gage blocks are precision machined to a very high tolerance and will include an inspection report that tells how much fault there is in the cake.

Practise NOT TRY TO TOUCH THE TOOL OFF THE GAGE BLOCK!

If you're using gage blocks, your cutter should not be spinning. But whether the cutter is spinning or not, it's bad for your expensive gage blocks and bad for your cutters. Instead, move the cutter up, stop moving, and try to slide the gage block between the cutter and the workpiece. At some signal, you will have jogged the machine a petty too far and can jog back until you lot tin slide between the 2.

Here's some other tip from a reader (thanks Paul!) if you don't want to use gage blocks–try a wrist pin from an engine. They're machined from hardened material, they're precise, they usually have a fine finish, and you tin roll them under the cutter to check the fit. In fact, from many standpoints, a cylinder or ball shape (big ball bearings are precise too!) makes a lot of sense for this measurement as they're less sensitive to whether the surface under them is flat and level. Have your micrometer to plant the wrist pivot's diameter and make sure information technology isn't worn too desperately if information technology's used.

When y'all have located the machine in ane centrality at a point you want to "Zero", your CNC Command volition have a way for you to tell it that's the aught for that centrality. This is an important operation, then make sure you know how to do it on your controller. There'due south commonly a one touch button to aught a given axis and peradventure some other to zero all the axes.

Note that y'all don't have to measure strictly Part Cipher. Your controller volition have a fashion for you to enter an capricious value in and tell it that is where the tool tip is currently located. This is convenient for many cases and something you'll exist doing fairly frequently too equally Zeroing. For example, you may desire to enter the thickness of your cigarette paper instead of "0.0000."

Border Finders and Probes for Establishing Work Coordinates

You lot won't be CNC'ing for long before yous'll exist wishing for an Edge Finder or a Probe. These are tools that make it quick and piece of cake to find the border of some object so you can Zero on information technology. Edge Finders come up in all shapes and sizes from simple spinning contraptions all the fashion to fancy, accurate, and easy to use contraptions such as the Haimer 3D "Taster". Yeah, that'southward not a misprint, they call them "Tasters" from the original German language.

Hither is a proficient video tutorial from Tormach on how to use a uncomplicated border finder:

A unproblematic edge finder…

And hither is a demonstration of a Haimer 3D Taster:

Haimer 3D Taster…

A probe tin be the ultimate in convenience for doing these kinds of Zeroing operations. Here is a Renishaw probe setting upward work offsets:

Renishaw probe setting up work offsets on a VMC…

Each of these tools is similar in purpose, but with increasing capability, automation, and expense. In that location are a wide diversity of other tools available for precisely locating features on your parts and workpieces. Some are more specialized, such as the Blake Coaxial Indicator, which is used to locate bore centers.

Yous'll desire to have some of these gadgets all stock-still up in a tool holder and fix to pop into your spindle for task setups.

For even more examples of how to observe Part Zero, run into our article which gives 8 ways to do locate Role Cipher.

Nosotros won't spend much more time on such things as they're more properly office of CNC setup and general machinist measuring techniques than 1000-lawmaking programming per se.

Even More Ways to Establish Role Nada

viii Ways to Locate Part Zero on Your CNC Machine

Exercises

1. Take out your CNC machine'southward manual and figure out how to cypher your CNC machine to institute Work Coordinates. Look upward how to read Machine Coordinates versus Work Coordinates on the command panel as well.

ii. Try some touch offs on your machine. Use the corner of a piece of chip stuck in a vise for starters until you get adept at it.

3. If y'all take an edge finder, 3D Taster, or probe, requite it a endeavour as a way of precisely locating role null.

4. Make up one's mind what your convention for Z = 0 and perhaps Part Zero will be and stick to it.

Yous've now got nearly all of the data yous demand to practise basic CNC Programming. You can make the CNC do anything a transmission machinist can do on a transmission machine.

Congratulations!

But don't stop now. Next upwardly is perfecting your skills by learning the remaining basic techniques. From there, take on some intermediate and advanced techniques. Don't worry, CNCCookbook has the manufactures that will enable y'all to just keep right on learning, step-by-step.

Bones Yard-Code Program Structure: Blocks, sequence numbers, words, addresses, and the basic nuts and bolts of g-lawmaking line.

Linear Motion: G00 and G01: Moving your CNC in straight lines.

1-Shot G-Codes and Modal One thousand-Codes: Some things in g-code are viscous and others are not.

Circular Arcs: G02 and G03: Moving your CNC forth arcs.

Round Arcs, Part 2: Tips for easier arc programming, arcs in CAM and Simulators, arc troubleshooting, and more than.

Tool Changes and Tool Offsets

Tool Length Offsets: Something every CNC machinist should know a lot about.

Tool Data Management: How do you go along up with all your tooling and the compensation information? What about tool presetting?

Basic CNC Lathe Programming: What'south unlike on a lathe versus a mill? Not likewise much, just information technology'southward important and this commodity takes you lot through it.

Quiz on Basic GCode Programming: Test yourself with a quick quiz on this section. Each question has links to the answers so you can review what you missed.

Intermediate G-Code

Relative vs Absolute Moves

Polar Coordinates

Canned Drilling Cycles

Custom Deep Hole Drilling Cycles

G96: Constant Surface Speed Programming

G98 Thousand-Code and G99 G-Lawmaking: Canned Cycle Return or Feedrate Modes

G04 GCode: Break / Dwell for Precise Timing

G61, G64, G60 G-Lawmaking: Exact Stop & Anti-Backlash for Precise Position

The K-Code Coordinate System Pipeline

G20 and G21: Unit of measurement Conversions

G54 and G92 Work Offsets: Making multiple parts easily

Helical Interpolation: Making holes bigger than any cutter you've got

Programming Borer: Rigid Tapping, Tapping heads and Tension Compression Holders

Programming Haas CNC Machines: Haas'southward unique g-codes and other differences

Thread Milling: How to thread mill, NPT and tapered threads, When to thread factory instead of tapping

Intermediate Lathe Programming

Lathe Simple Canned Cycles: G90/G92/G94

Lathe Repetitive Roughing Cycles: The Poor Man'due south Turning CAM

G71: Rough Turning Cycle: Blazon I

Using Mill CAM to Create Profiles for Lathe Cycles

G71 Type Two: Crude Turning With "Pockets"

G70: Finishing Cycle

G72: Rough Facing Wheel

G73: Pattern Repeating Cycle

Using IF and GOTO for a Poor Man'south G71

G75 and Peck Parting Off for Lathes

Lathe Threading Cycles

G76 Threading Wheel

Gang Tooling for Lathes

Advanced G-Code

G28: Return to Reference Point

Tool Compensation: The Poor Man's Milling CAM

CNC Macro Programming and Fanuc Macro B: A Mini-Tutorial on G-Code Macro Programming and Fanuc Macro B.

G10: Programming Tool and Piece of work Offsets in G-Code

G51: Scaling the Coordinate System

Rotating the Coordinate Organization with G68 and G69

Mirroring the Coordinate System

Chiliad-Code Scaffolding: Making CAM Improve With G-Lawmaking Help

Multiple Role Strategies

G52: Temporary programmable piece of work offsets

Interacting With the Operator

Tweaking CAM Programs: Right Angle Heads and More

Mill fourth Axis Programming

Lathe C-Centrality Machining and Live Tooling

Reference Motions

In-Process Probing

Resources

CNCCookbook Blog Posts Relating to GCode Programming: Lots more Tools, Examples, and detailed articles.

G-Sorcerer Editor: CNC Programming Software for g-coders and a CNC G-Code Simulator. We apply information technology in this class to aid teach Grand-Code.

G-Wizard Computer: A CNC Machinist's Computer

G-Code Reference for Mills

G-Code Reference for Turning

37 Things GCode Volition Do that CAM Won't

Sample Thou-Lawmaking Files: K-Code examples you tin download and play with

CAM Toolpath Strategies: Where plunge roughing, trochoidal machining, and other odd beasts are explained.

3D CAM Toolpaths: Larn the ins and outs of which 3D toolpaths to use in which situations.

Rhino Tips: Some of my tips and techniques for being productive with Rhinoceros 3D.

Fanuc's CNC Training Classes

G and M Code Programming Software Free Download

DOWNLOAD HERE

Source: https://www.cnccookbook.com/cnc-programming-g-code/

Posted by: bernicewaskepter.blogspot.com

Comments

Post a Comment